Suzuki 250cc Engine: An Analysis of Aluminum Die-Casting and Cooling Fin Technology

February 2, 2026

Suzuki 250cc Engine: An Analysis of Aluminum Die-Casting and Cooling Fin Technology

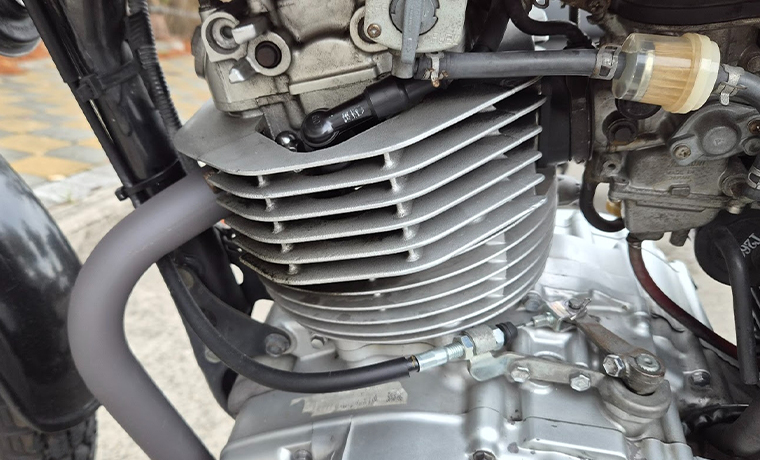

In motorcycle engine design, cooling efficiency directly dictates performance stability and service life. Suzuki has achieved a perfect balance between lightweight construction and high-efficiency heat dissipation in its 250cc class engines (such as the renowned SOCS oil-cooling system) by leveraging aluminum die-casting technology and optimized cooling fin designs.

The Advantages of Aluminum Die-Casting

Aluminum alloys possess an excellent thermal conductivity of approximately $200 \text{ W/(m·K)}$, significantly higher than traditional cast iron. Through die-casting technology, engineers can manufacture complex, thin-walled cylinder blocks with extreme precision. This not only substantially reduces vehicle weight and improves the power-to-weight ratio but, more importantly, allows the aluminum material to rapidly conduct heat from the combustion chamber to the engine surface.

Maximizing Heat Dissipation via Expanded Fin Area

The core principle of cooling lies in increasing the surface area in contact with the air. Suzuki’s design team utilized precise calculations to arrange dense cooling fins across the exterior of the cylinder block and head.

- Maximizing Fin Surface Area: By increasing both the depth and the quantity of the fins, the expanded total surface area significantly boosts heat exchange efficiency.

- Aero-Flow Design: The alignment and angles of the fins are optimized through wind tunnel testing, ensuring that cool air flows smoothly through the gaps to carry away heat while the vehicle is in motion.

- Oil-Cooling Synergy: Within the SOCS (Suzuki Oil Cooling System), cooling oil circulates internally to absorb heat, which is then radiated into the atmosphere through these large external fins. This approach eliminates the weight and complexity of a water-cooling system.

Key Data:

Experiments indicate that this optimized cooling fin design can reduce engine oil temperatures by 10–15% during sustained high-RPM operation. This is crucial for maintaining power consistency in 250cc single or twin-cylinder engines.