The Role of ADC12 Aluminum in Thermal Management

January 9, 2026

The Role of ADC12 Aluminum in Thermal Management

Among the various alloys available in modern metallurgy, ADC12 aluminum stands out as a cornerstone material for thermal management solutions. While it is used across numerous industries, its most prominent application is found in the manufacturing of high-performance heatsinks. The widespread adoption of ADC12 is not accidental; it is driven by a unique synergy between thermal efficiency and manufacturing versatility.

Exceptional Thermal and Mechanical Properties

The primary reason ADC12 is selected for heatsinks is its inherent ability to facilitate rapid heat dissipation. In power-intensive electronics, managing "thermal soak" is critical to preventing component failure. Beyond just moving heat, however, ADC12 is prized for its die-casting characteristics.

Unlike many other alloys that can be brittle or difficult to flow into molds, ADC12 possesses excellent fluidity. This allows engineers to design heatsinks with:

- Thin-walled fins: Maximizing surface area for air cooling.

- Complex geometries: Integrating mounting brackets and intricate internal channels directly into the casting.

- Weight reduction: Achieving high strength-to-weight ratios that are essential for portable or wall-mounted hardware.

Supporting the EV Revolution

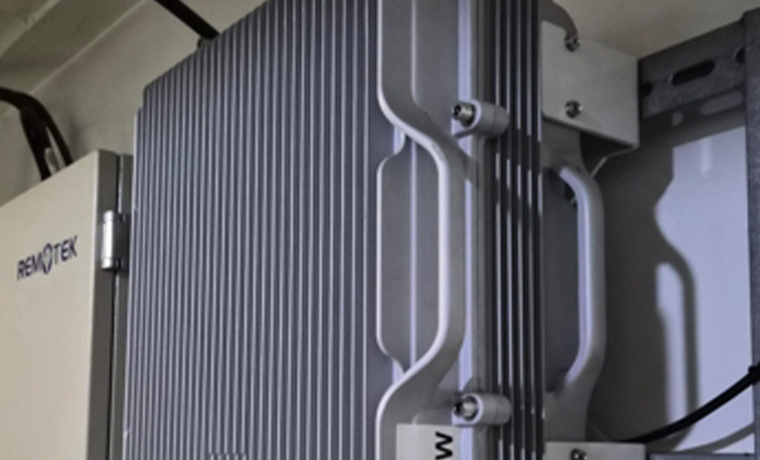

We are seeing a massive surge in the visibility of ADC12 in public spaces, particularly within Electric Vehicle (EV) charging infrastructure. If you look at the charging stations now populating parking areas worldwide, the rugged, metallic housings and cooling arrays are often made of this specific aluminum alloy.

EV chargers—especially DC fast chargers—generate significant internal heat during the energy transfer process. By utilizing ADC12, manufacturers can produce durable, weather-resistant enclosures that simultaneously act as massive radiators. This dual-purpose functionality ensures that the sensitive power electronics inside remain at optimal operating temperatures, even while sitting in direct sunlight or under heavy electrical load. As the demand for green mobility grows, the reliance on ADC12 to keep our infrastructure cool and functional will only increase.